One of the most common questions people have about shipping containers is what type of foundation they can sit on. Some things to consider are whether or not the ground is level or whether the container be moved at a later date.

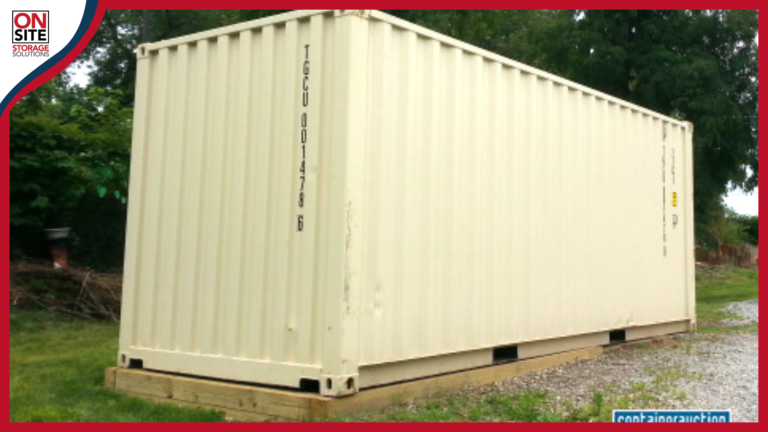

If you are not setting your container on a concrete pier foundation, or asphalt but rather on what we call “soft ground” such as dirt, grass, gravel, etc., it’s important to lift it off the ground to limit moisture underneath the container as well as to prevent it from sinking into the ground over time. Excessive exposure to moisture in the bottom of the container can lead to rust, damage, and corrosion.

Also, If the container slowly sinks into the ground over time this may eventually lead to difficulty in opening and closing the container doors because it may no longer be level. This is especially true if the container is stored in a wet or snowy climate.

Using railroad ties as the foundation for shipping containers above the ground is a cost-effective solution. They are pressure-treated to withstand the elements over time and come in 8’ lengths, perfect for the width of a shipping container. And, you only need two — one at each end of the container underneath the corner castings.

Tip: You can pick up railroad ties at most hardware retailers. Prices usually start at about $28.

There are several reasons why railroad ties are the best option for supporting a container. First, railroad ties are heavy and meant to withstand a tremendous amount of weight.

Most weigh around 200lbs and measure 8’6” long, 9” wide, and 7” thick. This size and weight make them an excellent foundation option for containers. Because they are heavy, you will need at least 2 people to move them into the right position.

Second, railroad ties are treated with creosote (tar) which protects the wood from termites and moisture. They’ll hold up even in the most extreme environment. If you use untreated wood, it will eventually rot and won’t last long.

They are also a better alternative to concrete blocks which may crush under the heavy weight of the container. To avoid this problem you would need to fill the blocks with cement to make them solid. Railroad ties can be used as is with no modifications necessary. They are cheap and easy to use and best of all, very effective.

Tip: As part of your preparation for the delivery, we recommend that you cut the railroad ties in half so that you have four pieces. This will make them lighter and easier to handle. It will also allow for a gap underneath the doors in case you need to lift the container with a bottle jack.

Watch the video below to see how to prepare railroad ties for the delivery of your shipping container. Refer to the actual steps listed after the videos on this page.

Watch – How to Prepare Railroad Ties for Storage Container

The video below gives an overview of the process from delivery to the installation of a 40-foot

shipping container. Note, 40-foot containers have 4 sets of corner castings: 2 sets in the front and 2 at the back.

Watch – Shipping Container on Railroad Ties

This video covers expert information from Gregg Schoenborn, Founder of On-Site Storage Solutions. The container in the video is a 20-foot container.

Follow the steps below to prepare the surface and railroad ties for your delivery.

Note: Shipping containers are extremely heavy and require specialized equipment. The truck and the trailer weigh over 45,000 lbs. You must make sure that the ground and site are level and hard to prevent the truck from getting stuck.

Placing the railroad ties on a flat, hard surface is important to ensure that all the railroad ties are level. This will ensure that all the corners are the same height and that the container floor is level. This will make it easier to open and close the container doors.

Before your container arrives measure the distance between the front and back railroad ties to make sure that you have the correct placement. For larger containers, measure from the second corner casting in front. (see picture below for reference).

Once you’ve measured the distance between railroad ties, remove the front railroad tie before the truck delivers. The delivery truck usually reverses to offload the shipping container. The truck cannot drive over the railroad tie so if the front railroad tie is still in place, the truck will get stuck which is why it’s important to remove it once you’ve measured out the site.

For larger containers, use the end set of corner castings, the ones on the very edge of the container.

The truck will drive forward allowing the container to lower to the ground gently. The truck should stop just before the front corner castings are loaded off the trailer to set the front railroad ties into position.

Just before the driver drops the front end of the container, reposition the front railroad tie so that it lies directly below the front corner castings. Slide the railroad tie into place pushing it from one end of the container to the other. For larger containers, position the railroad tie underneath the second set of corner castings (the ones furthest from the doors).

Before the truck drops the front end of the container onto the railroad tie it is important to follow proper safety precautions so that no one gets injured. Ensure that everyone stands clear of the container and truck while the container is being lowered and the truck is in motion. These containers can weigh up to 10,000 pounds and can be dangerous if tipped over.

After reading this guide, you have all the information on how to place your container on railroad ties. Keep in mind that some drivers cannot assist in placing railroad ties so plan accordingly. If you have any additional questions, contact On-Site Storage Solutions at (888) 405-8772.

Shipping containers can be placed on various types of foundations, including railroad ties, piers, concrete foundations, gravel pads, cinder blocks, and pile foundations. Each option offers different levels of stability and support. Factors such as climate, soil conditions, and project requirements should be considered when choosing a foundation. Seeking guidance from professionals or structural engineers can ensure the best choice for specific needs.

Railroad ties are rectangular wooden pieces with specific measurements that are utilized to maintain a consistent distance between steel rails in a track. They play a crucial role in keeping the rails securely in place and ensuring the stability and integrity of the railroad infrastructure.

Railroad ties, also known as sleepers, are traditionally made from wood such as oak or mixed hardwood. However, other materials like prestressed concrete, steel, and even plastics have been used for railroad tie construction. Wood remains the most widely used material for railroad ties, accounting for a significant majority of the ties in use today.

Railroad ties can typically be purchased at most hardware retailers, and prices generally start around $28. These retailers offer a convenient option for acquiring railroad ties for your landscaping or construction needs. It’s advisable to check with your local hardware store or visit their website for the most up-to-date pricing and availability.

Shipping containers are available in various sizes, with the most common being 20 feet and 40 feet long. The width and height of a standard container are around 8 feet and 8 feet 6 inches, respectively. High cube containers have an added foot of height, measuring approximately 9 feet 6 inches tall.

When it comes to anchoring railroad ties to the ground, there are several methods you can use. One common approach is to use rebar, which involves cutting it into suitable lengths and pounding it into the ground through pre-drilled holes in the ties. Another method is to bury the first row of ties and secure them together with steel spikes or lengths of rebar. Additionally, using bolts specifically designed for this purpose can be effective in securing the ties when building retaining walls.

Want to upgrade your outdoor area and make a special cooking space? Think about changing your backyard with creative shipping container kitchen concepts. By adding

Are you looking to save some money when purchasing shipping containers? Whether you need them for storage, transportation, or a creative project, getting a good

Welcome to the exciting realm of Shipping Container Offices – a modern way to create a cool, customizable, and budget-friendly workspace. If you’re a business

In the world of storage and moving stuff around, 20 ft standard shipping containers have been super important for a long time. They’re tough and

When it comes to how shipping container doors work, there are many types to choose from to fit different needs. Knowing which door type to

A container chassis, an intermodal chassis or skeletal trailer, is a specialized semi-trailer built to transport intermodal containers securely. These chassis are vital in freight

Ⓒ 2023 On-site Storage Solutions | All Rights Reserved